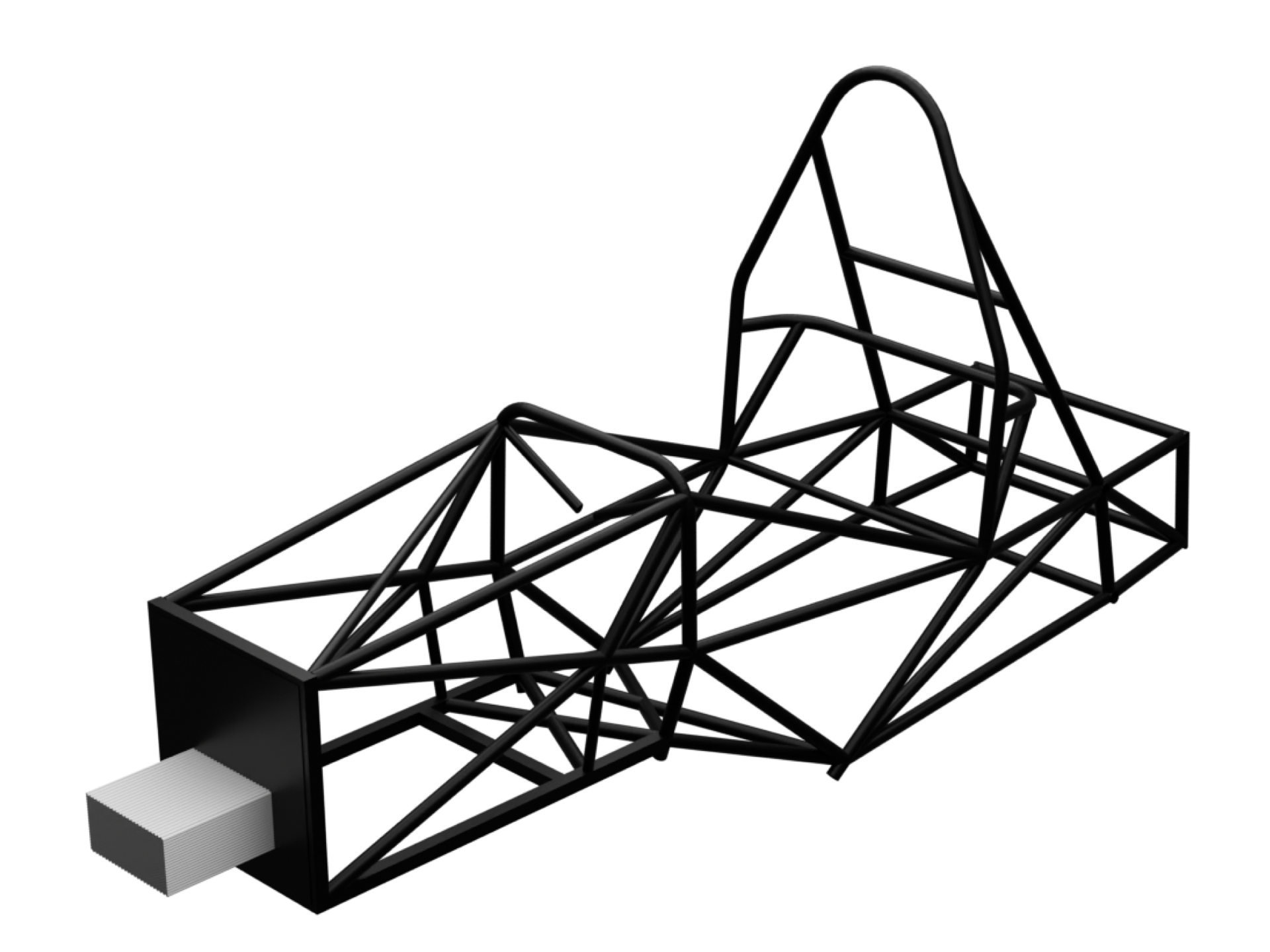

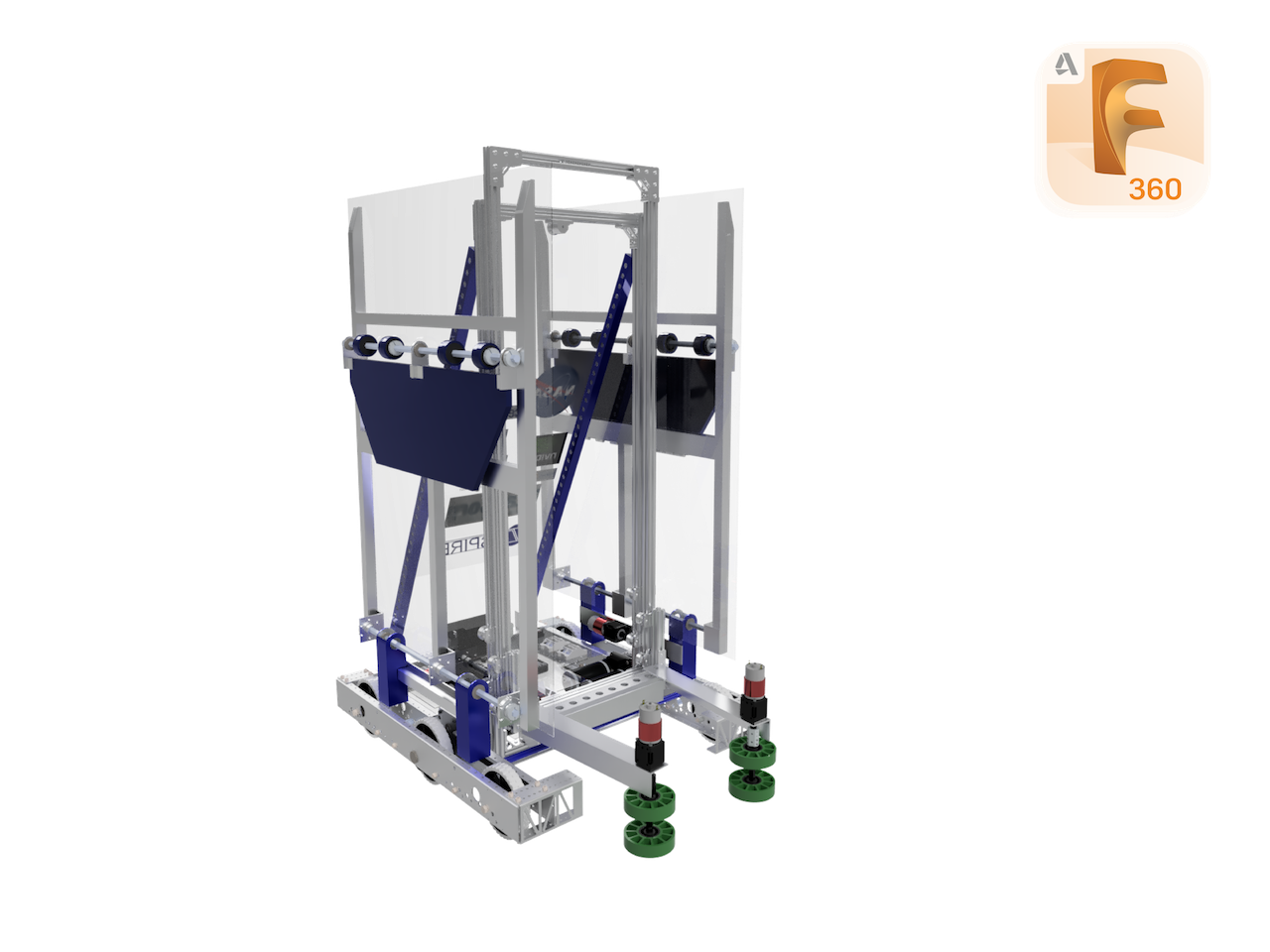

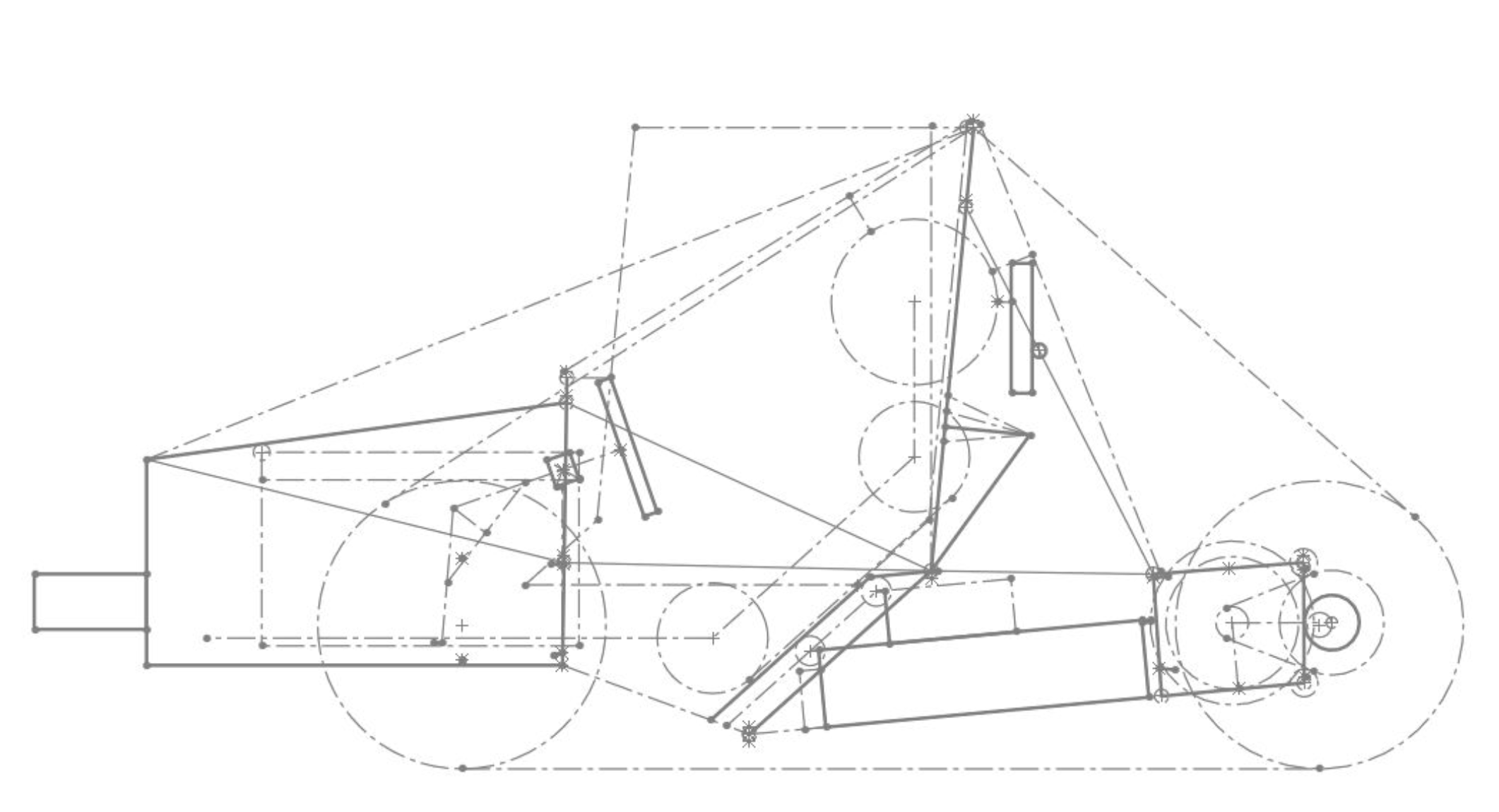

FSAE - 2024 Spaceframe

As chassis lead of Formula Electric at Berkeley (FEB) I led spaceframe design for the car. With a primary goal of packaging optimization and weight reduction,

I served as the integration engineer for the entire car, working with every subteam to fit every component while making compromises to lower weight and welding effort.

Despite challenges imposed by our workspace operations and usage hours, I created a team of TIG welders for the first time for our club, with members switching on and off the car everyday from 8-6.

We jigged and welded the entire car in less than 2 weeks, less than half the time from our previous year. After 100+ hours of welding time myself, we sent out the car for powder coating as well.

This year was the first year we built and ran a torsion test on our chassis as well. A torsion test measures the torsional stiffness of the chassis, a major factor in the handling characteristics of the car.

Over the course of the year, we design an modular system, manufactured it in house, and tested our car, correlating to within 10% of our simulation.

With more simulation iterations upcoming, we hope to refine this number further and develop this process for the future of the club.